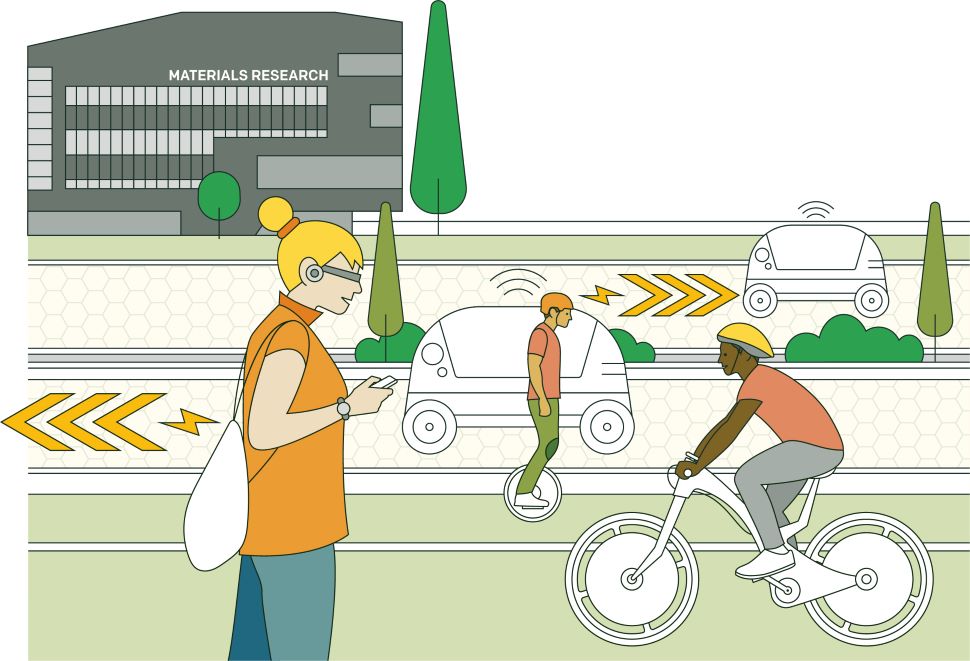

Manchester’s international reputation for innovation is entering new realms — with an ambitious community of experts, next-generation materials, new investment, and big plans for the future.

Recognized as one of the most innovative cities in the world, the city that was at the center of the Industrial Revolution, is delivering new global firsts that are shaping cities and lives of tomorrow – from the built environment and transport, to healthcare, our food chain, and carbon reduction.

Home to world-leading institutes, Manchester is nurturing strong collaborations between business and academia – and demonstrating its ability to turn ideas into reality. Here we meet some of the people, places, and thinking behind Manchester’s latest innovations in advanced materials and the future of manufacturing.

Material Innovators of Manchester

Two scientists at The University of Manchester made history in 2004, when they isolated graphene for the first time, and went on to be awarded the Nobel Prize for Physics. The super-strong, single atom thick material, can be used in a wide range of applications, from aerospace engineering to digital electronics and biomedicine – and Manchester has now seen more than £300million investment into its graphene and advanced materials discovery and adoption ecosystem.

Major facilities, including the Henry Royce Institute for advanced materials, National Graphene Institute (NGI), and the Graphene Engineering Innovation Centre (GEIC), are supporting research and commercialization of new products. Latest advances include new sustainable construction materials, graphene-enhanced medical and public health innovation, water filtration technologies, and a revolutionary farming system.

James Baker, CEO Graphene@Manchester, said: “Advanced materials can transform the way we live. Innovation in advanced materials offers the disruptive potential to make us completely rethink how we build our future cities – making them both greener and smarter.

“What we’re trying to do here in Manchester is not just great science but also accelerating its application into new technologies – and to achieve this, we are building the supply chain needed to bridge the gap between academic breakthroughs and market-ready products. A pioneering ecosystem we call Graphene City.”

New view of farming

The new farming system being developed in Manchester can drastically reduce the amount of energy and human interaction required to produce food using ‘vertical farming’ techniques and help address food supply concerns.

Graphene scientists are developing an intelligent soil alternative known as GelPonic that can sense and respond to a plant’s nutritional needs. It is being led by Dr. Beenish Siddique, founder and CEO of AEH Innovative Hydrogel, who said: “We believe there is an opportunity here to change the future of farming not just here in the UK but around the world. Globally, around 70% of the fresh water available to humans is used for agriculture and 60% of that is wasted; agriculture also contributes around 20% of global greenhouse gas emissions. Our system helps control that waste and those emissions, shortens germination times and could enable an increase of 25% in crop yields.”

The business is now growing its operations and has received £1million as part of the government funding for technology to assist UK farming, as well as support from the European Regional Development Fund (ERDF).

Health Innovation Inspiration

Manchester is leading research that will reimagine the delivery of healthcare and new technological advances to support it. Earlier this year, the Christabel Pankhurst Institute for Health Technology and Innovation opened as part of an ambitious plan set out in the Greater Manchester Local Industrial Strategy. The multi-million-pound research and innovation facility builds on Manchester’s academic strengths in digital health and advanced materials.

Innovation happening across Manchester’s healthcare landscape is vast – and combines work by the NHS, public sector, and academics, along with pioneering businesses and entrepreneurs.

One business with a personal story to tell is South African-founded, ProMake. Back in 2015 its owner, Jason Laing, suffered life-changing injuries in an accident and became the subject of a personal experiment, using 3D printing technology to design, manufacture, and repair parts of his body, saving his arm from the risk of amputation.

ProMake moved its headquarters to Manchester in 2019 due to the city’s strengths in health innovation and advanced materials. It received European Regional Development Fund (ERDF) funding – via the Bridging The Gap programme based at the GEIC – and more recently has been appointed to Public Health England’s National Microbiology Framework. Prompted again by personal experience, the company is now developing Covid and public health-related innovation – including graphene-based biosensors for virus testing and antibacterial material for public spaces. It has also introduced the world’s first accessible commercial graphene 3D printing portal, with potential for use across many industries, including healthcare, construction, automotive, and aerospace.

CEO and Co-founder of ProMake Ltd, Jason Laing, said: “3D printing itself excites me because of the possibilities that it can bring about, and what it has done for me already. 3D printing with graphene is a major game-changer. We couldn’t have achieved what we have without the support, collaboration and partnerships we have built here in Manchester – with universities, advanced materials specialists and other organisations with a shared vision for innovation.”

Concrete proof

Last month, Manchester’s ambitious Mayfield regeneration scheme – set to deliver transformational change at the eastern gateway of the city centre close to Piccadilly Station – made its mark in history with the use of Concretene, a new graphene-enhanced concrete that has the potential to transform the global construction sector.

Designed to improve the mechanical performance of concrete, it allows reductions in volumes of material and the need for steel reinforcement and can deliver up to a 30% reduction in CO2 emissions. The Mayfield project was the first commercial use of Concretene in a suspended slab and another step towards testing and development as a substitute for concrete on an industrial scale.

Meanwhile, graphene is being put through its paces for new roads, with a world-first resurfacing trial on the A1 road in the North of England, supported by experts in Manchester. This could see operational life of infrastructure extended, reduced frequency of roadworks and smoother journeys.

Life Beyond Earth

Following this series of world firsts for graphene in the built environment, work is also underway on graphene-enhanced habitats beyond Earth — to raise the technology readiness level (TRL) of new lightweight composites using 2D materials for space applications.

With demand for space habitats expected to grow over the next decade, Dr. Vivek Koncherry is leading a project with the GEIC and global architect firm Skidmore, Owings & Merrill (SOM) to research the design and manufacturing for the space industry. He said: “A major barrier to scaling up in time to meet this demand is the lack of advanced and automated manufacturing systems to make the specialist structures needed for living in space. One of the space industry’s biggest challenges is overcoming a lack of robotic systems to manufacture the complex shapes using advanced materials.”

Machines of Tomorrow

Manchester is at the heart of the UK’s largest manufacturing and advanced materials cluster, with continued investment to support commercialization of new innovation.

The major new Advanced Machinery & Productivity Institute (AMPI) in Rochdale will be tasked with creating the new machines and technology needed to manufacture tomorrow’s products and materials. It joins other specialist facilities in the city-region, such as the University of Salford’s Autonomous Systems and Robotics facility, Manchester Metropolitan University’s Advanced Materials & Surface Engineering Research Centre, and the GEIC at The University of Manchester.

Innovation plays a fundamental role in Manchester’s economic vision. It recently launched Innovation GM, which is a blueprint for a partnership with the Government that aims to create up to 100,000 jobs, raise R&D investment and generate a £7 billion economic benefit across the city/region.

Reality of 2038 Net Zero

With its own target of being carbon neutral by 2038, low carbon has become a driving force for innovation for the city/region itself, as well as for global markets.

Lou Cordwell, Chair of Greater Manchester Local Enterprise Partnership, said: “With specialist expertise in advanced materials and a commitment to green growth, Greater Manchester now has an opportunity to influence global innovation as we move towards that low carbon future.

“This opportunity goes beyond shaping the future built environment. Identifying sustainable energy sources, solving transport challenges and answering fundamental questions about how we will provide a growing global population with food and water are vital.”

Tim Newns, CEO of MIDAS, the inward investment agency for Manchester, which helps businesses who are developing a base or expanding in the region, said: “As we progress our journey to net zero in 2038, I would like to think there’ll be a little bit of Greater Manchester in every city-region around the world, taking some of the technology and learnings from our own ambitious journey in order to achieve their own net-zero status.

“But this requires global collaboration. The science and forecasts behind our own plans for net zero transition tell us that we need significant innovation in order to reach our target. If we were to implement the technologies available to us now, then we wouldn’t hit our 2038 net zero target, therefore we need to overcome the ‘innovation gap’. So the call is out to companies from around the world — if you want to innovate in new low carbon products or services, and you want to do it in a place where you can demonstrate capability at scale, and where there is the supportive ecosystem to help you succeed, then Manchester is the place.”

Material Gains

In a city known for new thinking, we have only touched the surface of the innovation happening in Manchester and the giant leaps being taken in the research and commercialization of new ideas. For an in-depth look at Manchester’s advanced materials community and its vision for cities of the future visit the Material Gains report here.

MIDAS is the inward investment agency for Manchester and provides free support, consultation, and expertise to help businesses who are expanding or establishing new roots in the city/region. It supports strong innovation links between business, academia, government, and the public sector.

Find out more here www.investinmanchester.com/powering-innovation