By 2050, over 40 percent of the world’s population will live in severely water-stressed areas. Many reading this are likely not surprised by that number, as it’s a topic we’ve quietly come to accept. Water, it seems, is not a human right. Though it’s easy to get lost in startling statistics, there is hope. Scientific breakthroughs are changing the way we solve these monumental problems and they’re doing it in surprising ways.

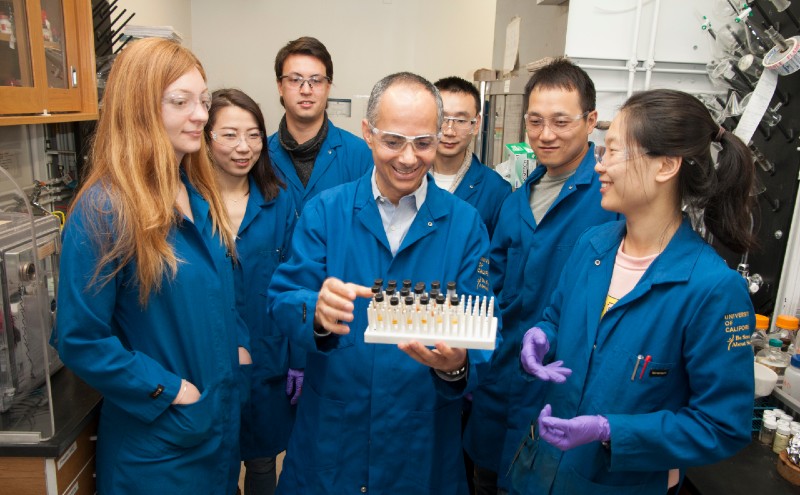

UC Berkeley Professor of Chemistry Omar Yaghi was chosen as our Innovator of the Year precisely because he’s solving these problems, and not just the water crisis. His remarkable discoveries can harvest carbon dioxide from the atmosphere. They can store methane and natural gas, offering a solution to some of the biggest concerns facing the renewable energy movement. And yes, his discoveries allow desert-dwellers to collect drinking water from thin air.

Omar Yaghi developed metal-organic frameworks (MOFs). Though most people have never heard of MOFs, they could hold the key to solving some of the world’s most pressing problems. They’re chemical structures which can be formed into materials that are capable of astounding things, like the ability to absorb and release vapors. MOFs can be used to capture greenhouse gases from the atmosphere, to harvest water from the driest of desert air, or cleanse toxic chemicals from the air we breathe.

We shared Yaghi’s abridged interview in our 5-Year Anniversary issue and here he offers even more insight into his discoveries.

Innovation & Tech Today: How did you first become interested in chemistry?

Omar Yaghi: I became interested in chemistry when I was a kid. I was ten years old and went into a library where I found a book that had drawings of molecules, which I didn’t know anything about. I didn’t even know that they were molecules, but the drawings looked complex and interesting and they captured my attention. I kept that with me. Later I learned they were molecules, and so chemistry became my favorite topic.

It’s strange how a passion for things develop, but it’s also strange how we pick the things we pick. I was very interested in knowing, “What is this?” “What is behind things?” “Why do things look the way they do?” And as a child, I was very interested in what is behind what you see, what is it made up from? And what are the smaller and smaller parts of matter? And that’s why chemistry was just captivating to me.

I&T Today: What is a metal-organic framework (MOF) and why is it significant?

OY: It’s a chemical structure in which inorganic units, multi-metallic clusters, are linked by organic units. The best way to illustrate a MOF is to think about it like a scaffolding. The intersections would be inorganic metal oxide units, while the rods that link the intersections would be the organic units.

The reason MOFs became so important is that we figured out how to link the organic and the inorganic units with strong bonds. That’s the basis of a new field I termed reticular chemistry.

The resulting structures are robust and encompass space, and that space can be described in terms of surface area. You can think of it as a footage of the material, just like footage of a house. MOFs are the real estate onto one can trap molecules and gases, like hydrogen, methane, carbon dioxide, and the latest is water.

When you use multi-metallic units, units that have two or more metals as intersections, and link them up with organic you make very nice architecturally robust structures. We showed that they can be permanently porous. Meaning when you evacuate their pores, the structures don’t collapse and remain open. So early on we discovered a MOF which had a surface area that broke all records of porosity. All previous records, everything that humanity has ever made, this [porosity] was much higher. And we’ve continued to break our own record many times since then.

People are enamored by the porosity but that is just one property among hundreds of new things that reticular chemistry has brought forward.

The excitement about porosity is fueled by the fact that it gives you the ability to have interesting properties like hydrogen storage or water capture or carbon dioxide capture. Very, very important applications, but you cannot appreciate the fullness of this area unless you step back and say, “Well, what has this area meant for the whole of chemistry?” It is a whole new branch of chemistry that is about control of the strong bond. In developing reticular chemistry, we have combined organic chemistry and inorganic chemistry, two large fields that are taught separately, and in fact treated as separate disciplines. We’ve combined them together into one area, with all the advantages that those two fields bring, plus what reticular chemistry also offers is the porosity and everything that you can do within the pores to control matter further.

I&T Today: It sounds like so much of science, where there’s all of this really fantastic work going on at a deeper level, but often all we talk about are the applications of that knowledge.

OY: Yes, when you say, “Oh, I can harvest water from desert air and deliver water.” That’s a very important thing to be able to do and yes, I think the public likes to hear these things because they can relate to them. Not very many people outside of chemistry are interested in the details of how this was generated? And the way it was generated is that somebody like me, who was interested in intellectual challenges, not necessarily applications, especially when we started this research. The intellectual question we set out to address was how do you make materials using a building block approach? A kind of LEGO chemistry?

I took that risk as an assistant professor with the hope of tenure one day, I took this big risk that paid off. Once we made them, once we demonstrated that you can build structures by molecular building blocks, we realized the potential is great.

We were the first to demonstrate the use of MOFs for hydrogen storage, methane capture, carbon dioxide capture, and now water.

I&T Today: I’m fascinated that water storage wasn’t your intention when you started. Particularly given that you grew up in an arid region and obtaining water was a persistent problem for your family, and somehow without intending to, you’ve developed this technology that can be applied to solving that problem.

OY: I think it also brings up another very important point, and that is the way great things happen in science is by answering intellectual questions, not necessarily picking a societal problem and trying to find a solution to it. Meaning, when you solve an intellectual challenge, it branches out into an infinite number of things that you can do for society. But if I started out with water from air, I would have had to work backwards and then think, what materials are available for that application? Well, I would never have discovered and developed MOFs and later covalent organic frameworks (COFs). Never. Because I would have been in an engineering like mode where you use the existing stuff to try to test whether it’s going to be good for harvesting water or carbon dioxide and that would have never worked, because those materials wouldn’t have the new properties that emerged from the new materials that we’ve achieved as a result of answering an intellectual problem.

I&T Today: Perhaps that’s why it’s so important to instill those ideals in children, through STEM, where instead of thinking about end results and answers to problems, they are willing to ask questions and be curious.

OY: One of the biggest mistakes we make when we teach young kids, I call them emerging scholars, is that we always think, if I don’t give them a practical thing that they can think of, like harvesting water from air, I’m not going to get their attention. It turns out everyone, young or old, is stimulated by good questions. They can be on the basic science level or they can be on a practical level. The mind is hungry for stimulation and it’s just a question of howwe present that question?

I was really more intrigued with the question of could I develop chemistry where I can use the infinite number of molecular building blocks that exist as my starting materials and stitch them together into extended structures? And that was our original motivation. My motivation wasn’t necessarily directly to save humankind through carbon capture, but I knew very well that if I succeeded in answering that basic question that there would be many interesting and fascinating applications that could solve some big problems in society. So it was a serious goal as my future as a scientist was on the line. If I failed, I would be kicked out of the academic structure, and I would have to find a job that I may not be passionate about.

It was a very serious affair that required a tremendous amount of work from myself and my group to put this area of research on solid footing.

I&T Today: So if you didn’t intend to create a material with these capabilities, when did you realize MOFs could harvest water from dry air?

OY: We were working on carbon capture. We were the first to conceive materials that could capture carbon dioxide. One of the things we noticed is that because carbon dioxide is always emitted with water, that water goes in and occupies the very adsorptive sites where CO2 binds. So the material very quickly became inefficient. We needed to devise a way of being able to go after CO2, pluck it out of a gas mixture in the presence of water, without water complicating that.

We made a material and then designed its interior so that it specifically can work in the presence of water. It can take up CO2 and the presence of water actually helps the binding of CO2, that’s just the magic of being able to control the chemistry of the MOF pores. Then we noticed there were certain structures that took up water in a way that was very special and doing so at very low humidity. Our initial experiment was at 20 percent relative humidity.

Of course, there are materials that take up humidity at 20 percent, like zeolites, but the special thing about our material is that you can take the water out at mild temps (45 degrees Celsius). But for zeolites and minerals, you have to heat them up to much higher temperature to remove the water. Therefore, you couldn’t use them in the end to capture water from air and then deliver drinking water efficiently.

That was one of the most powerful things that we noticed; you can capture the water at low humidity and also take it out at mild temperature, almost the temperature of the desert during the day. The second unique thing is that the way the water goes in and out is through a cooperative mechanism, where the first water molecules enhance the ability of the material to take up more water from the atmosphere. That was the second important discovery.

We looked at this and I said to my students that this would be perfect for binding water from the atmosphere at night (in the desert) when it’s a little bit more humid and then during the day when it’s hot you can remove the water and you can make, potentially, if you have a way to condense that vapor, drinking water. And that was the beginning of the water harvesting project.

Now we have devices that deliver one liter of water per kilogram of MOF per day, as we demonstrated in the Mojave Desert. I have co-founded a company called Water Harvesting Inc. in Silicon Valley and we can already produce 10 times that per kilo per day. The idea of being able to create a material that would take up moisture from low humidity and bring water to regions that don’t have water is feasible. We showed that it works in the desert.

I&T Today: How quickly do MOFs degrade?

OY: The power of not just being able to design a structure but being able to go in that structure and modify it so that it does exactly what you want is what reticular chemistry is all about. This is what reticular chemistry brought into the chemistry of materials. The MOF will be in the [water harvesting] device for the lifetime of the device. The device lifetime is really the lifetime of the electronics, which is 5-6 years. Thus far our tests are on track for the MOFs staying in the harvester for the lifetime of the harvester.

The interesting thing is that after five or six years, if the MOF indeed is not in its optimal form, you can take it out and do the reverse reticular chemistry, separate the metal from the organic and then reassemble them back to the perfect MOF. You don’t have to throw it away because it’s constituents are not damaged. It does follow a zero discharge cycle.

I&T Today: How could MOFs be applied to filtration technology? For example, could one place a MOF within a gas mask to capture toxic gases?

OY: You can change the pore size and the pore environment, meaning if I want to trap organic molecules that may be in water, not only do I need a pore size that would fit that molecule, but also I can go in and specifically modify the interior so that the environment can attract that molecule in high capacity and selectivity.

That has great applications for, let’s say if you have a volatile organic compound or a nerve gas, you can design the interior in such a way that you can trap a target molecule and only that molecule. You can also design the interior so that once they’re in the pore, they can be destroyed by strategically breaking certain bonds that make them less harmful. You can design the MOF so that it’s selective, but also you can design it so that it can do chemical operations on that bound molecules like a factory.

Some of these building units that we are using today were known back in the 1930s and 1940s. So why did it take until 1995 for someone like me to come along and develop this field?

The answer, I think, is that in every field you have dogmas. It was widely believed at the time when I started that this chemistry can’t be developed for various reasons. These beliefs were based on the wrong assumptions. And it just takes one person to say, “You know what? I don’t agree. I’m going to take a risk and try and delve into this chemistry and make it work.” That’s how discoveries and progress are made.