In a short space of time, 3D printing has gone from science fiction to home entertainment. The technology has moved out of laboratories and commercial settings and into the home.

The hardware needed to get set up in 3D printing is now accessible and affordable to anyone with an interest. 3D printing is exploding, but the ease of access to this hobby belies the complexity of 3D printing.

Here are 7 essential tips for 3D printing beginners.

Calibrate

Calibrating your 3D printer is the first thing you need to learn how to do if you want to produce accurate designs. And you may as well get adept at it right away. If your printer isn’t calibrated properly, even your tester cubes might come out wrong, let alone more complex objects.

To calibrate your printer, a set of digital calipers will be essential — this will allow you to identify the exact dimensions of the test objects you produce. Print off a batch of basic objects – cubes, and other items with nice angles, and apply your calipers to check for accuracy.

It’s Hip To Be Square

3D printing is a craft and it takes time to learn the subtleties of creating great objects. Familiarize yourself with the process of 3D printing — as well as the nuances of your own device.

Printing out lots of 20mm square cubes will help you get into the flow. Cubes don’t have to be boring though – you can experiment with hollow items and then cut cross-sections to ensure your printer is producing accurate perimeters.

Take Your Time

Expectations of 3D printing often don’t live up to reality and it’s going to take time before you’re printing off functional items that can be put to use. Embrace the learning curve and accept that it’s going to be a while before you can call yourself a master.

A Complex Object Is Greater Than The Sum Of Its Parts

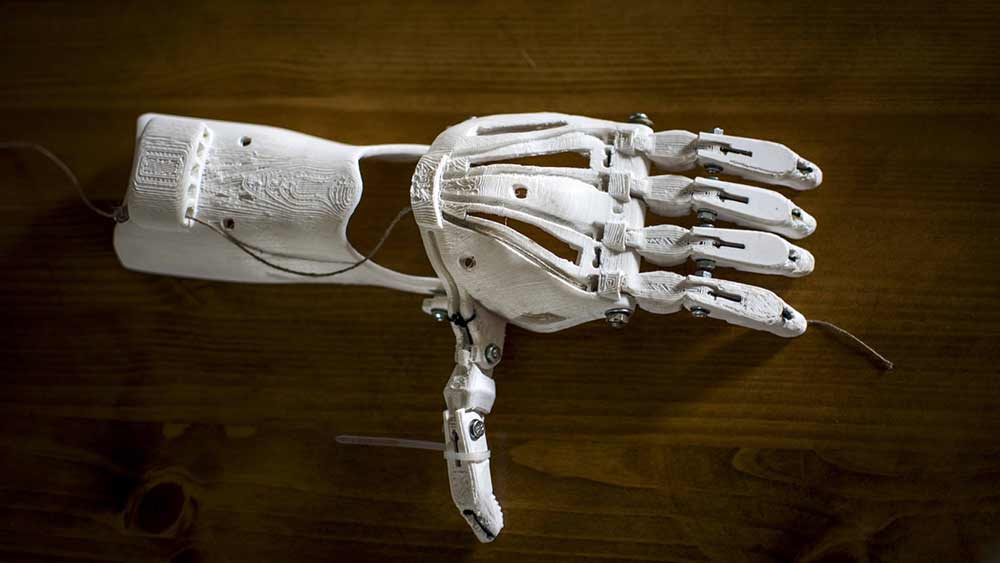

Once you pass the ‘cube stage,’ you’ll graduate to more and more complex objects. As you build up to these challenges, start out by printing complex objects from your printer that come to fruition when assembled by hand. Printing off multiple simple objects is less of a risk, where with complex items even one small error can cost you an entire project.

Learn CAD Alongside Your 3D Printing Journey

CAD (computer-aided design) is an essential component of creating fantastic 3D printed shapes. These designs are what gets fed into the printer, informing the final output.

Whilst many who get into 3D printing never approach this software, preferring to use other people’s designs, learning the basics of CAD will give you more freedom to explore your passion. Starting from scratch in the software and finishing with a product in your hands is the ultimate in satisfaction.

Margins: The 0.25mm Rule

Assembling complex objects from your 3D printer is great, but nothing is more frustrating than when your hard-earned designs don’t fit! This is where the 0.25mm rule comes in – it gives you the necessary margin to ensure all your moving parts fit together.

For example, if you’re planning on inserting a 20mm pole into a block, make the diameter of the hole 20.25mm. This quarter mil’ gives you the necessary margin.

Dive Into The Community

There’s a thriving 3D printing community out there and these forums hold the answer to countless questions. 3D printing forums are not only full of valuable information, they’re a place to source new designs and find inspiration.

3D printing is a popular hobby because of its complexity, not despite it. This complexity has created a huge community that’s waiting to help you develop your 3D printing journey.

3D printing isn’t just a great hobby — it’s an opportunity to learn new skills and create functional items. You never know, it could even become a career.

These 3D printing tips are going to help you on a journey from noob to 3D printing sensei – just remember that it takes time to get there.

Lauren Groff is a 3D printing professional and editor at Paper Fellows and BigAssignments. She prides himself as an entrepreneur and innovator and, to this end, enjoys keeping abreast of digital trends