3D printing gained recent popularity as a tool for hobbyists, enabling them to create anything they can design in a modeling program. However, even back in the 1980s, when the first incarnation of the technology emerged, it was designed for manufacturing. The technology has finally reached a point where widespread implementation is becoming feasible. Here’s how automotive manufacturers are taking advantage of 3D printing.

Making Prototyping More Efficient

Prototyping a new car or improving existing models has always been a time-consuming process. Once the design is down on paper, it’s up to engineers and artists to make it a reality. This can be a quick process for small models, but the prototyping process can take up to three months for large or detailed ones. 3D printing car parts can reduce the time it takes to prototype something new to a handful of days.

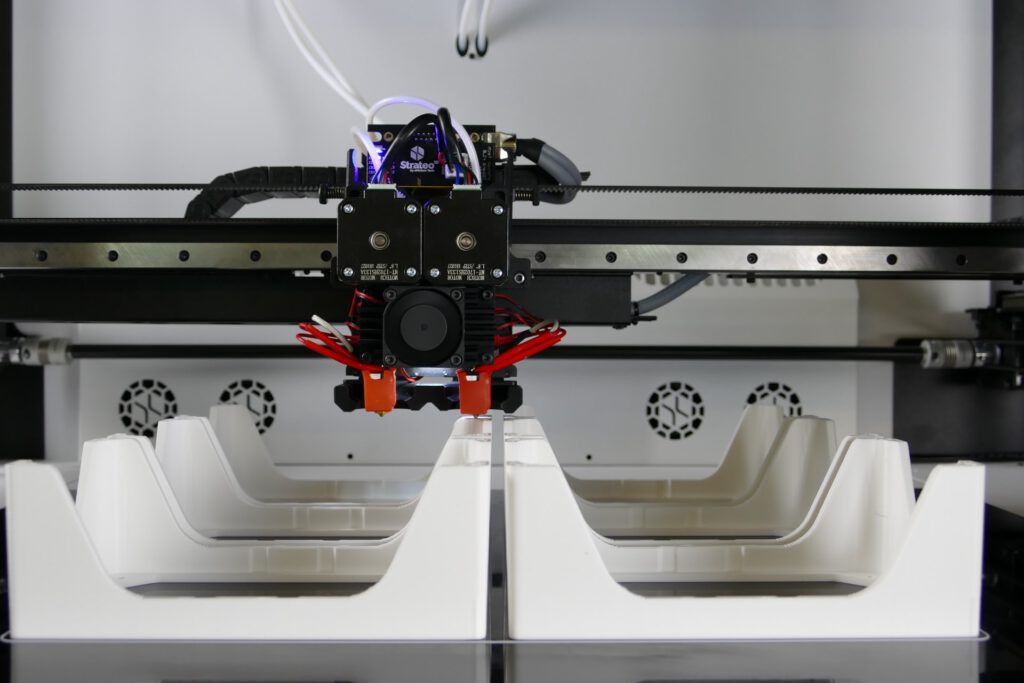

These prototypes aren’t just limited to plastic models anymore. Modern printers can manufacture designs in plastic, resin, metal, glass, or even complex materials like graphene, carbon fiber, and Kevlar. Anything an engineer or automotive designer can come up with in a 3D modeling or computer-aided design (CAD) program can be turned into reality in less than a week.

Increasing Production Speed

Automotive manufacture has become a pinnacle of efficiency ever since Henry Ford introduced the assembly line in 1913. Putting together a car, which used to take upwards of 12 hours, was reduced to a mere two hours and 30 minutes. 3D printing may not reduce that, but it has the potential to improve overall production efficiency, lessening slowdowns and keeping the industry moving forward.

This shift toward faster production will become essential in the following decades as automotive manufacturers move away from internal combustion engines (ICE) and switch their focus to electric vehicles. According to industry experts, ICE cars will continue to grow through 2030 before finally beginning to taper off. When they do, millions will be replaced with fully electric or hybrid models.

Introducing Advanced Materials

Advanced materials like carbon fiber and Kevlar are starting to become more common in automotive manufacturing. For example, Ford is investing in machines from a company called Impossible Objects, which specializes in advanced materials in its 3D printers. It’s also investing in Desktop Metal, which produces printers that can create with metal, as well as large-size printers that could be used to construct bigger pieces of an automobile. Even some of the electronic components used to keep these cars running could be 3D printed in the future.

3D printing in materials other than plastic is beginning to emerge in other industries as well. You can find massive concrete printers that can build an entire house in a couple of days in the construction industry or delicate bioprinters in medicine that enable doctors to print tissues or even organs made from the patient’s own cells. The potential applications for these technologies are limitless.

Offering Easy Personalization

One of the coolest things about 3D printing from a consumer perspective is the fact that it gives everyone the ability and opportunity to create something uniquely theirs. The same opportunity will likely exist in the future for automotive personalization and customization. While consumers will still be building on a base model and frame, options can turn that daily driver into something no one has ever seen before.

BMW recently launched a new additive manufacturing campus in Munich, and Mini — one of its brands — is already offering custom-printed 3D panels and accessories that owners can choose from.

Eventually, within reason, consumers may even be able to design their own custom vehicles from the ground up. There will be certain regulations that must be followed to ensure they are street legal and safe to drive, but beyond that, these projects may only be limited by the creator’s budget.

Contributing to Mass Reduction

The average car can weigh anywhere from 2,900 to 3,500 pounds or more, depending on the make and model. The heavier the vehicle, the worse its fuel efficiency becomes. Fuel efficiency is becoming one of the most important features of new cars with the worldwide push toward sustainability — at least until the industry transitions from internal combustion engines to fully EVs.

Opting for 3D printed parts, especially ones made from plastic or other lightweight materials, can reduce the overall vehicle mass and improve fuel economy in one fell swoop. Plastic might not be the best choice for some components, but with 3D printers emerging every year that can work with everything from steel to carbon fiber, there is bound to be something for everyone.

Producing Rare Parts

Automotive 3D printing isn’t just useful for creating new vehicles. It’s also becoming a valuable tool for keeping classic and antique cars running. This is especially true for models that have been out of production for decades and require specific parts that aren’t made anymore. Porsche Classic, the division of the luxury car company dedicated to maintaining and restoring vintage vehicles, started using 3D printing to produce rare parts for its antique cars.

This is invaluable for classic Porsche owners who might receive something that hasn’t rolled off an assembly line since before they were born and is one of the most unique uses for 3D printing out there. This isn’t the sort of printing that the average hobbyist can do, with Porsche carefully guarding its 3D models. However, it’s a lot more efficient — not to mention safer and easier — than scouring a junkyard for the pieces you need.

Work Smarter, Not Harder

There are a lot of changes on the horizon for the automotive industry, with the push toward abandoning internal combustion engines in full swing. 3D printing is starting to take its place in this sector and will likely shape the way we assemble cars for the foreseeable future. It’s a way for manufacturers to create and offer vehicles that are efficient, unique and cost-effective.