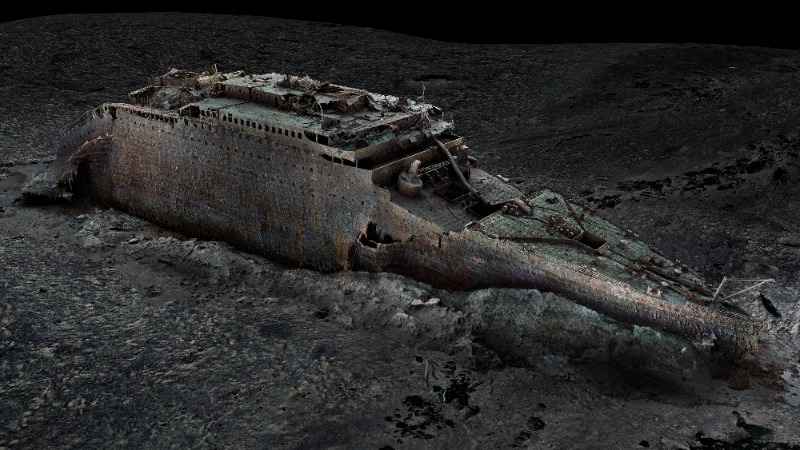

On April 11, National Geographic viewers can see a groundbreaking scientific achievement unlike anything seen before in Titanic: The Digital Resurrection. At the core of this docufilm lies a technological breakthrough—an exact full-size digital twin of the Titanic and its surrounding wreckage, captured with millimeter-level accuracy.

Until now, researchers studying the shipwreck could only glimpse fragments. But with the help of advanced scanning technology, the Titanic can finally be explored in her entirety—just as she rests today, more than two miles beneath the surface.

We spoke with William McMaster, the film’s lead and technical director, who led the effort behind these never-before-seen visuals and the historical revelations that emerged as a result. For the first time, scientists can walk the ship’s decaying halls—virtually—and uncover insights that have remained hidden for over 110 years.

Innovation & Tech Today: Let’s start at the heart of this project: How did you approach creating such a precise 3D scan of the Titanic? What technologies made this possible?

William McMaster: So, before this project, most of the scanning work I’d done was on land—large-scale scans. This was actually my first time scanning anything underwater, so the approach had to be completely different. Everything had to be captured using ROV submersibles, and to be honest, there was a steep learning curve.

I brought my experience with 3D scanning, while the others on the team were experts in diving and operating submersibles—but not in scanning. It was very collaborative. I’d ask things like, “Can we go over there and capture from that angle?” and the ROV pilots would explain, “No, because of X, Y, and Z limitations.” So I learned a lot quickly.

Ultimately, I was the one who understood what we needed for the final product—those finished 3D models—so we worked together closely. I’d ask, “Can we get this?” and if the answer was yes, we’d move forward from there.

I&T Today: A collaborative effort for sure. From a tech standpoint, what would you say was the most challenging part of the expedition?

McMaster: I’d say there were two main challenges: equipment failure and capturing enough data from enough perspectives.

We were in the middle of the ocean—if something broke, we couldn’t exactly run to the store. So we had backups of everything: hard drives, gear, supplies. But even then, stuff goes wrong. These ROVs are massive—think small car size, weighing as much as a Range Rover. Most people imagine something dishwasher-sized, but it’s much more complex. And when you’re working almost 4,000 meters underwater, extreme conditions mean stuff breaks. If something disconnects or fails, the ROV has to come all the way back up, and a team of techs would get to work—replacing parts, welding, and repairing on the fly.

That unpredictability caused delays. We’d have to pause, sometimes for 12 hours, then pick back up exactly where we left off. That was tough.

The other challenge was photogrammetry—most of the model was created through still images from multiple angles, stitched together to form the 3D model. Photogrammetry only works with what the camera can see, so we had to plan every angle. The wreck is incredibly complex—bars, debris, and structures sticking out. It was like solving a 3D jigsaw puzzle.

We spent about a month, working 24 hours a day in two shifts, to collect all the data.

I&T Today: As you were uncovering all that data, were there any scientific discoveries or surprises that stood out to you?

McMaster: Definitely. I’m not a Titanic expert—I’ve always been interested in it since I was a kid, but we didn’t have top-level Titanic experts on board. We had people with deep shipwreck knowledge, but a lot of times I didn’t know what I was looking at until later when experts examined the data.

Two things really stood out to me. First was the bow section—that iconic “king of the world” spot. We spent a lot of time flying the ROV around there. It’s so famous, so being able to capture it and really study it in 3D was amazing.

Second was the portholes. There were hundreds along each side of the ship, and many were open. That really hit me. It’s a wreck, there’s no life left down there—but seeing those open portholes reminds you that people were there. You imagine someone opening one, maybe shouting for help. Being that close, seeing that kind of detail—it stays with you.

I&T Today: Given the sensitivity of the site, how did your team balance technological innovation with respect for the Titanic and the lives lost?

McMaster: There were strict guidelines. We weren’t allowed to fly the ROVs inside the wreck. There are areas—like where the grand staircase used to be—where it might’ve been possible to go in, but it wasn’t permitted.

We had to maintain a specific distance—just a few meters away—to avoid damaging anything. The ROVs are huge and heavy; getting too close could knock something over or puncture the wreck. The entire operation was designed to be as non-invasive as possible, keeping the ship as intact as we found it.

I&T Today: I want to touch on your background in land-based scanning and immersive video. How has your approach evolved—especially through this project?

McMaster: I actually started in 360 video, back when VR was having its resurgence around 2012–2013. 360 video is still really cool, but it’s limited—you’re stuck at a single point in space. You can look around, but you can’t move through it or interact.

That’s what drew me toward 3D scanning and capture. With 3D models, you can walk around, pick up, and interact with objects. It adds a whole new layer of immersion. So I gradually shifted toward scanning real-world places and environments. Working on the Titanic project felt like a natural evolution of that—taking the tools and knowledge from land-based scans and applying them to something this historically significant.

I&T Today: How do you hope future generations—or even current scientists and viewers—will use or learn from this digital recreation?

McMaster: The technology to do this has only recently become available. This is the first true 3D model of the Titanic at this level of detail.

The wreck is slowly collapsing over time, so what we’ve done is create a snapshot of how it exists now. I think in 50, 100, or even 1,000 years, people will look back at this model as version one—the first comprehensive digital record.

Eventually, the wreck will be gone. But this model will endure. It’ll be relevant today, but also invaluable to future generations—scientists, historians, and everyday people alike. I think people will always be fascinated by the Titanic and the stories behind it. Now they’ll have a way to see it up close, long after it disappears from the ocean floor.

Titanic: The Digital Resurrection premieres on National Geographic on April 11 and streams on Disney+ and Hulu on April 12!