Just when we thought we’ve seen it all, a new technology emerges that puts actual products in our hands — through an amazing printing process.

Recently, I was stunned when my eyes rolled across a headline: “Dad uses 3D printer to make his son a prosthetic hand.” I had to go back and read it twice. A father whose son was born without fingers spent two years searching for an affordable way to give his son the ability to grasp, pinch, pick up, and hold items with a prosthetic. His search was futile. Then he came across 3D printing. Using the 3D printer at his son’s school, he was able to design and fabricate a prosthetic.

The mere thought of this remarkable event tells me why this industry will grow in a steep curve over the next few decades. The applications almost seem limitless, and as many businesses strive to find intangible web-based technology, companies such as Afinia, MakerBot Industries, Cube, EOS, ExOne, Fab@Home, Materialise, Objet, Optomec, ReaLizer, RepRap, Shapeways, Stratasys, and 3D Systems fight for the top spot in a tangible technology.

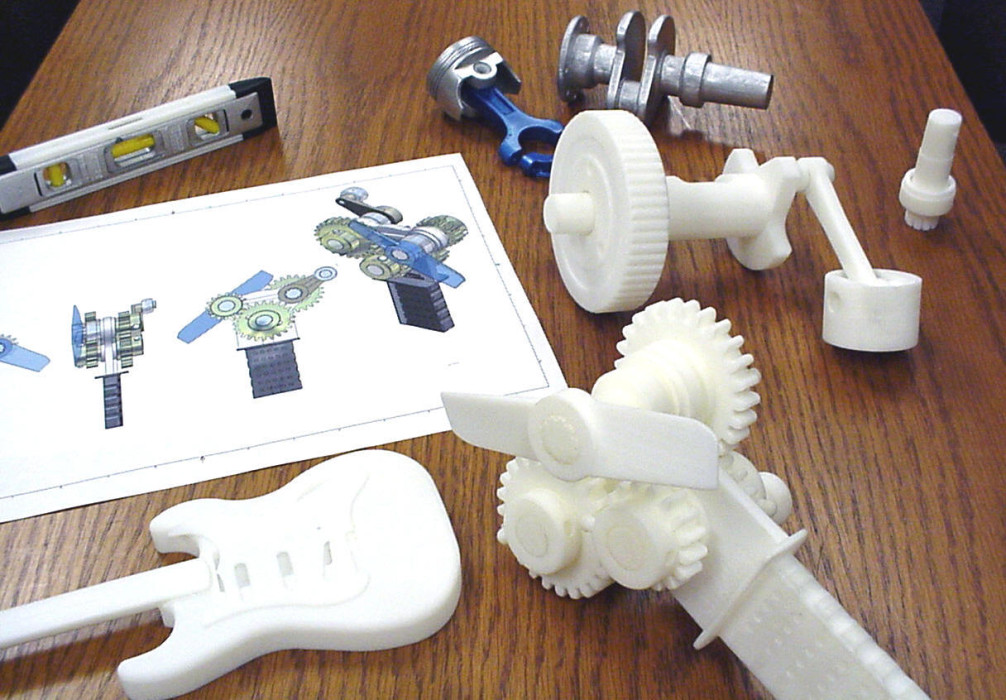

What is 3D printing? Or, if you want to use its official name, Additive Manufacturing? In simple terms, 3D printing is just as it sounds: printing a solid object of nearly any shape using a digital model. Think about a sci-fi movie where a person lays in stasis while tiny arms quickly rebuild their musculature system. It’s quick as it replicates what once was there, or should have been. That’s 3D printing. Of course, at the moment, that kind of technology is still a ways away, but with industries jumping board such as architecture, engineering, aerospace, dental and medical fields, as well as dozens of others, the replication of an arm is not as far off as it may seem.

Much of this will be determined by the materials manufacturers can use when making products through 3D printing. Currently, there are two types of materials from which most items are printed, ABS (Acrylonitrile Butadiene Styrene) and PLA (PolyLactic Acid). Opinions vary, but ABS is usually cited as slightly better due to its material integrity (it won’t shatter as PLA has a tendency to do). It can be tapped for screws, as well as a surface that can be more easily finished in post-production. Let’s face it, though: replication of an arm won’t be done with a rigid material. This is where the future becomes fun, as new recyclable, organic, and potentially living cell tissues are used to create the future of medical surgery and manufacturing.

Stepping away from sci-fi for a moment, let’s look at the short history of the industry. The concept began to take root in the 1980s with a man most credited for developing the language of the modern 3D printer, Charles W. Hull. The eventual co- founder of 3D Systems, Hull coined the term “stereolithography”. We’ll touch on that specific term later, as the 1984 patent defines current 3D printing technology.

The concept has always been a simple one. The printers work much like an inkjet printer, except instead of ink, material is layered in successive patterns until an object is created. By the early 1990s, the new technology was proving, although imperfectly, that small parts could be built. When we reached the new millennium, scientists had created the first lab-grown organs for urinary bladder augmentation.

Then, in 2006, manufacturing connected with mass customization. Two years later, that really expanded thanks to growth in prosthetics and an opening of the door to smaller companies and home-based businesses such as artists, architects, and designers to print out physical and inexpensive copies of their designs. In 2011 came the arrival of world’s first 3D printed car, the Urbee, and in 2012 a 3D printed prosthetic jaw was implanted in an 83-year-old woman.

In his seminal 2011 report, “Additive Manufacturing and 3D Printing State of the Industry Annual Worldwide Progress Report,” leading market analyst Terry Wohlers made predictions for a robust second half of this decade (see story on page 68). He also focused on the Urbee car, a big hit when it was revealed at the TEDx in Winnipeg in late 2011. The 3D printed car can get 200 miles per gallon and reach 70 miles per hour. From a printing process? Can you imagine?

It’s obvious that 3D printing technology has grown quite a bit in the last 25 years, but where is the boom? 3D printing is growing rapidly, but not yet at the explosive pace we’ve come to expect in technology. As Wohlers’ report noted, though, that explosion is just about here. In fact, most experts say 2014 is the year of explosive change in 3D printing, as many of the industry’s important patents expire. That will inevitably lead to a market flooded with more advanced and competitively priced 3D printers backed with big investors. For the current market leaders, 2014 will be a productive, yet scary year, as industry movement from Asia, more specifically China, is sure to jump on better technology at lower cost. What does this say for the market leaders such as Afinia, MakerBot, and Cube?

Afinia’s initial growth could be linked to social media and web surfing, but in 2012 a review by Make Magazine listed Afinia in their “Ultimate Guide to 3D Printing,” with awards in Best Overall Experience, Easiest to Setup, and Easiest to Use. This helped the young company achieve a good position in the market. Said Mitch Ackmann, President of Afinia and Microboards, “We will sell no 3D printer before its time. There are no venture capitalists or public shareholders telling us to release products prematurely. We have our own schedule and we follow it.” Ackmann explained that the third factor in Afinia’s success has been due to their parent company, Microboards Technology, and their dedication to design,

engineering, logistics, supply chain, infrastructure, and customer service. Customer service is key. Afiniacs, as their customers are called, lend support through praise on social media, while the company responds with good old- fashioned customer service. They are big enough to fill orders of hundreds of printers, while small enough to call each customer to thank them for their business. In an industry burgeoning with new young competition, Afinia is posed to hold fast and grow in the 2014 boom.

Afinia currently holds the number three spot in market leaders, while MakerBot and Cube hold the top two spots. They will likely maintain the top spots due to strong public relations, name recognition, and support from their parent companies.

We’ve discussed some of the obvious applications of 3-d printing, mostly in the medical, engineering, and automotive fields. But, what is its future

across the full spectrum of industry and business? The potential seems almost limitless. Consider McDonalds, for example. I’m not talking about replicating a Big Mac, but what if you are at McDonalds and your child wants a specific toy with their Happy Meal, and that toy is no longer available? Well, McDonalds IT Director, Mark Fabes, has been seriously thinking of adding in-store 3D printers for such cases. “Countless families have had their enjoyment of a nutritious McD’s ruined because they turned up the week that the starring character in that season’s kiddie-sized blockbuster had been replaced by an earnest but boring supporting character as the toy of choice,” Fabes said.

Now imagine the advances in Wi-Fi. You would be hard pressed to not be able to find a free Wi-Fi service within a few miles in any major city, and often small towns. What if the same soon holds true for free 3D printing? In Abingdon, Maryland, this dream is coming to fruition. The Hartford County library was gifted a 3-d printer for public use. While it is used mostly to print smaller objects such as key-chains, smaller toys, and iPhone cases, they believe there will be growth of more compli- cated items, with education playing a big part.

Afinia’s Ackmann sees our country’s economic growth in Science, Technology, Engineering, and Math, STEM. (In a side note, the 2014 STEM Forum & Expo is expected to draw thousands of young enthusiasts, teachers and others to New Orleans). None of this should be surprising, yet just like the computer, internet, and e- readers, Afinia has realized the potential of getting 3D printing into schools. To that extent, the company has partnered with Pitsco Education and Project Lead the Way to introduce curricula integrated with 3D printers. That way, educators receive a classroom-ready solution for their STEM curriculum needs.

This leads to young minds probing a new technology and the creation of a better world. For example, a small impoverished community in Africa may one day be able to use recyclable materials to print everyday items, such as kitchen utensils, that are not readily available. With small amounts of funding, this process is starting to take shape.

Homemade prosthetics, manufacturing your own iPhone case at the public library, and print- on-demand happy meal toys are starting to make this technology, once only available to financially- backed engineers and scientists, a strong reality for the rest of the world. The highly anticipated 2014 boom will be bringing about less expensive, more robust, and advanced technology to at-home consumers, non-profit companies, and impoverished areas of the world. Then the latest technology boom will really hit strong.

By Stephanie Clarke

(Update)

What a difference a few years makes! As of February 2017 companies such as XYZprinting have put 3D printing within anyone’s budget with offerings such as this $270 device. Easy-to-use software and an auto-calibration feature make the da Vinci Mini a great 3D printer for novices, and you’ll get clean, smooth prints at decent speeds. (Printing at higher resolutions slows things down considerably, though.) You’re restricted to using PLA filament from XYZ, but since that filament isn’t expensive, that’s a fair compromise to make for an attractively priced 3D printer with good-looking output.