For decades, the engine of industry has been fueled by a simple, linear model aptly known as “take, make, waste”. We extract raw materials, manufacture products, and at the end of their life, we discard them. This model gave us the modern world, but it’s running on fumes. In an era of volatile supply chains, fluctuating resource prices and a clear climate imperative, clinging to this outdated process isn’t just irresponsible, it’s a critical business error.

The future of manufacturing and profitable enterprise is sustainable and circular. This isn’t about planting trees for PR or aiming to meet minimum compliance standards. It demands a fundamental redesign of how we create value. It’s about building resilient, efficient and innovative businesses that are insulated from the shocks of a linear system. TERREPOWER is staking its future on this principle, and I believe every leader in the tech and innovation space must do the same.

The High Cost of Inefficiency

The take-make-waste model has always had hidden liabilities. We are now seeing them come due. Relying on a constant stream of virgin materials makes a company intensely vulnerable to geopolitical instability, trade disputes and simple resource scarcity. When the price of lithium, cobalt or copper spikes, the shockwave is felt from the C-suite to the consumer. Waste not only causes environmental problems, but also economic inefficiency. Every item sent to a landfill represents squandered materials, energy and labor—money literally thrown in the trash.

In this context, sustainable manufacturing isn’t an alternative; it’s the solution. The business case is no longer theoretical. It’s a clear-cut competitive advantage built on three core pillars:

- Economic Resilience: By reducing reliance on virgin materials and minimizing waste, companies slash costs on two fronts: procurement and disposal. More importantly, they build a more stable, predictable and resilient supply chain by creating their own source of high-quality materials from returned products.

- Market Demand: Whether consumers or B2B clients, customers today are savvy. They demand transparency and are increasingly making purchasing decisions based on a company’s environmental footprint. Companies with strong emphasis on sustainability tend to be better managed, incur less long-term risk and provide a better value proposition for their customers. Sustainability is now a powerful brand differentiator.

- Talent Acquisition: The brightest minds of the next generation don’t just want a paycheck; they want a purpose. They want to work for companies that are solving real-world problems. A robust sustainability mission is one of the most powerful tools a company has for attracting and retaining top-tier talent.

These and other benefits of sustainability are gaining recognition in the business world. TERREPOWER’s value proposition is delivering high-quality, sustainably manufactured aftermarket parts that meet or exceed OEM standards—at a significant cost advantage. This provides clear benefits to our customers, the environment and all stakeholders.

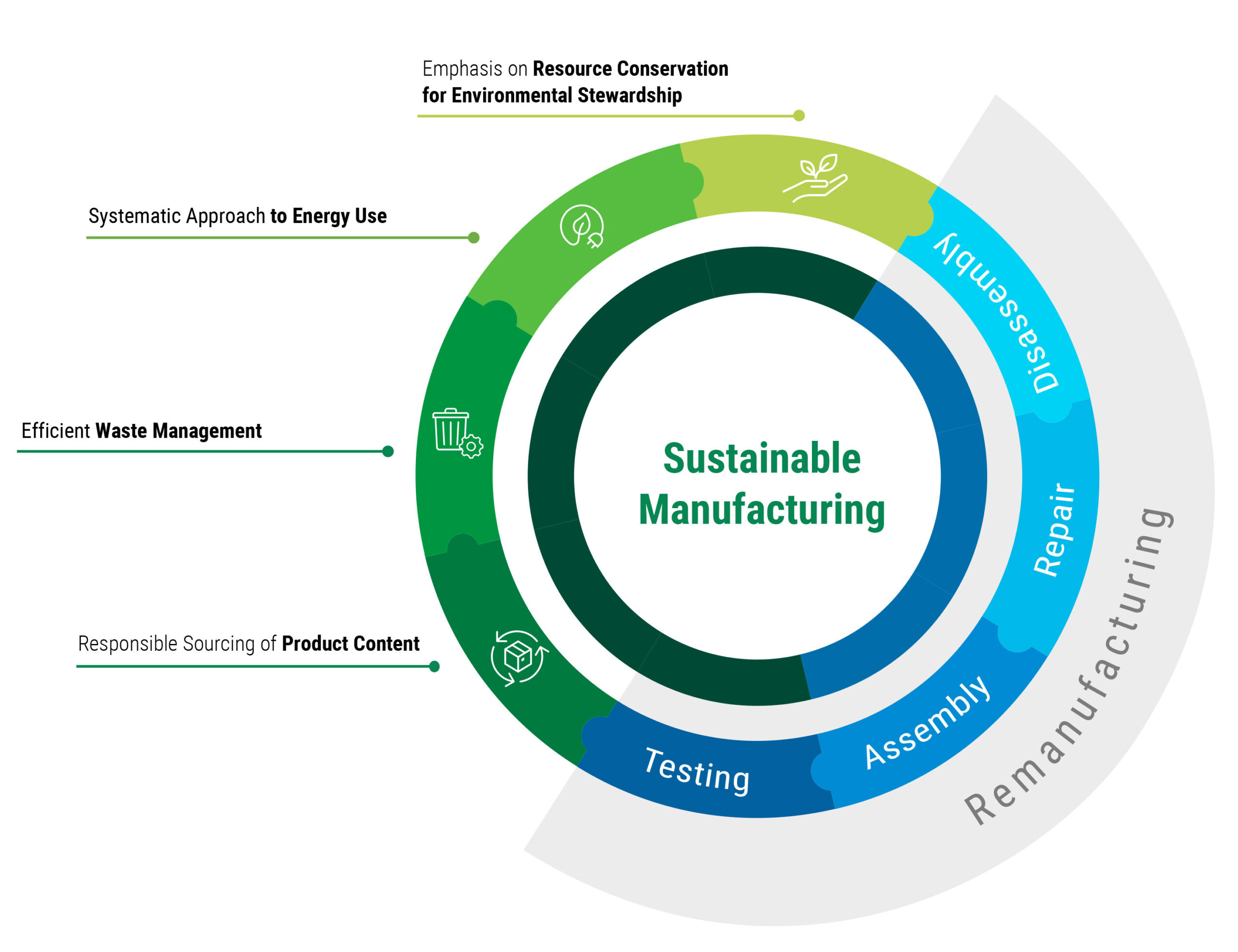

When people hear “sustainability,” they often think of recycling. But recycling is the last resort. It’s an energy-intensive process that breaks a product down to its base commodities, destroying all the value added during manufacturing. The real engine of the circular economy is a much older, more elegant concept: remanufacturing.

Manufacturers Are Embracing the Quiet Path to Transformation

There is a quiet path to modernizing your shop floors and factories. Emphasis on quiet, because “Digital Transformation” has always been loud, louder, and loudest. It causes strain on the organization’s resources… Continue reading

Remanufacturing: An “Old” Idea Fueling New Innovation

Remanufacturing is the process of returning a used product to at least its original performance, with a warranty to match. It’s not mere repair; it’s a rigorous, industrial-scale process of disassembly, cleaning, inspection, part replacement and reassembly. Far from being a throwback, it is becoming a hotbed of technological innovation.

Where traditional remanufacturing extends the life of automotive and industrial parts, TERREPOWER’s sustainable manufacturing processes deepen the impact of remanufacturing by also prioritizing responsible sourcing, efficient waste management, a systematic approach to energy use and resource conservation for environmental stewardship. Our success reflects both the exceptional value of our components for end users and the benefits of smarter sourcing, which keeps business flowing amidst market uncertainties and supply chain disruptions.

Here’s how sustainable manufacturing is forcing us to be better engineers and smarter business leaders:

- It inspires better design. When you have to think about taking a product apart, you start designing it differently. Remanufacturing forces a shift to design for disassembly. This leads to modular products that are easier to service, upgrade and harvest components from. The result is a more durable, longer-lasting product that provides more value to the customer and the manufacturer.

- It demands advanced tech. How do you efficiently diagnose the health of a thousand returned lithium-ion batteries or solar panels? You develop sophisticated testing protocols, AI-driven diagnostic software, and robotic automation to handle and process components. TERREPOWER is constantly innovating its technology to more accurately grade the state-of-health of battery cells and pinpoint microscopic defects in solar panels, turning what was once considered e-waste into a predictable, high-quality resource.

- It creates invaluable data. The remanufacturing process is a goldmine of data. Every product that comes back tells a story about how it was used and why it failed. This creates a powerful feedback loop directly to R&D. By analyzing this data, companies can identify common failure points and design flaws, leading to rapid, data-driven improvements in next-generation products. You learn far more from a product’s end-of-life than you ever can from a lab.

The Path Forward

The transition to a circular model is the single greatest business opportunity of our time. It’s a chance to build stronger, more profitable, and more resilient companies. By embracing sustainable practices and investing in the innovative potential of sustainable manufacturing, we can move beyond the brittle, wasteful model of the past.

We can turn our waste streams into value streams, our environmental liabilities into economic assets, and our supply chains from a global risk into a local, circular strength. The technology is here. The business case is undeniable. The only question is which leaders will have the foresight to seize the opportunity.