It wasn’t long ago that 3D printing was almost mythical, with limited technology and capabilities.

Now, we’re inundated with 3D printing technology—digital light processing (DLP) being one of them—producing more precise, detailed, and incredible designs. And it’s an industry generating massive revenue, a global total of $3.56 billion in 2024, with a lot of that being pumped back into innovation.

DLP is one of the most popular 3D printing technologies with huge capabilities. But how does it compare to other 3D printing devices?

Read on to find out.

What’s Digital Light Processing 3D Technology?

DLP (or Digital Light Processing) is a form of robotic polymerization (we’ll later). With DLP 3D printing, everything happens simultaneously—an image of the entire layer is shown at once.

When it comes to accuracy, speed, sharpness, and the amount of time it saves, DLP is arguably the most efficient. Courtesy of the digital illumination projection, the precision is unparalleled. Edges are of the cleanest sharpness, and surfaces are smooth.

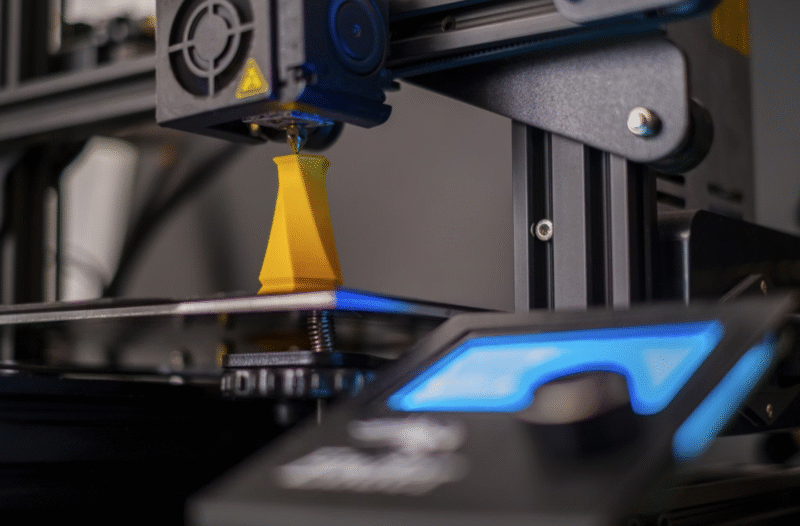

While we have FDM printers that sequentially deal with rigid polymers robotically, the DLP projector goes full-scale. It projects smoothly and projects each layer individually.

Another feature is fewer moving components. That translates to fewer potential problems and less time spent troubleshooting. You set your design, press print, and the light does the rest.

How Does It Stand Out From Other 3D Printing Technologies?

Let’s face it, there’s no perfect all-in-one solution in 3D printing. But if you’re after a specific laser focus, it doesn’t just stand out. DLP is boasting.

Fused Deposition Modeling, or FDM, is an entry-level drug. It’s inexpensive, but not as dependable. And it’s competing for the least attractive printer award. You’ll notice layered lines, scrub for the residue after the print, and you’ll cuss under your breath if the print warps or suddenly stops halfway.

Stereolithography is an improvement. It has smooth surfaces and solid details but is painfully slow. Watching paint dry, level slow. The laser painstakingly traces each curl and corner, which is beautiful but time-consuming.

Then there’s Selective Laser Sintering. It’s a strong, gritty industrial printer. It melts powder into exceptionally strong parts, but good luck affording it if your garage doesn’t double as a NASA lab.

Now let’s talk about DLP again. DLP offers the speed of SLS while still providing the finesse of SLA. It does everything quickly while still maintaining high-quality standards. DLP completes tasks meticulously without being slow. DLP works best for smaller parts that require precision rather than forceful strength.

Essentially, it’s just better.

What Point Are We At With 3D Printing Capabilities?

The buzz phase is well behind us.

After struggling for a while, the sector seems to be recovering again. And by 2030? We’re looking at a global market worth over $40 billion.

It hasn’t stopped; it just matured. Materials are getting better, cheaper, and wider in variety. You’ll see titanium implants, aerospace parts, and even conductive materials for smart devices. 3D printing is gradually reaching the level of CNC machining and even injection molding.

With AI joining the party, the fast pace will only get faster. More intelligent designs, less guesswork, faster certification, and simpler workflows will lead to lower costs and improved quality. Expect greater quantities, reduced hassle, and enhanced efficacy.

We are witnessing rapid growth in the world of 3D printing. New technologies are emerging, machines are becoming more advanced, and adoption rates are rising. And with the technologies merging, DLP is advancing at full speed, offering solutions that lead the market.